Automatic Transmission

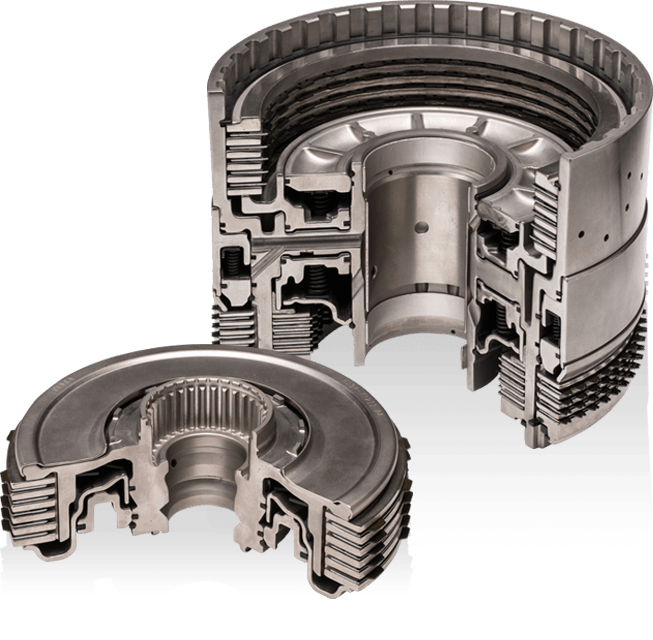

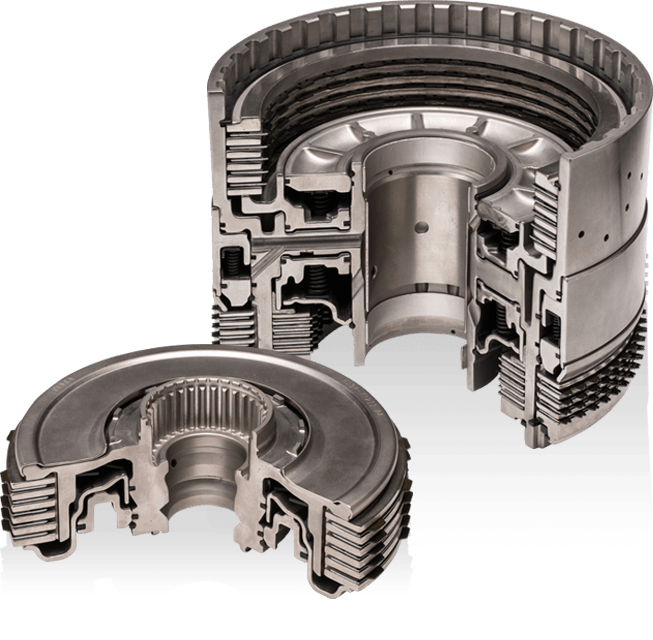

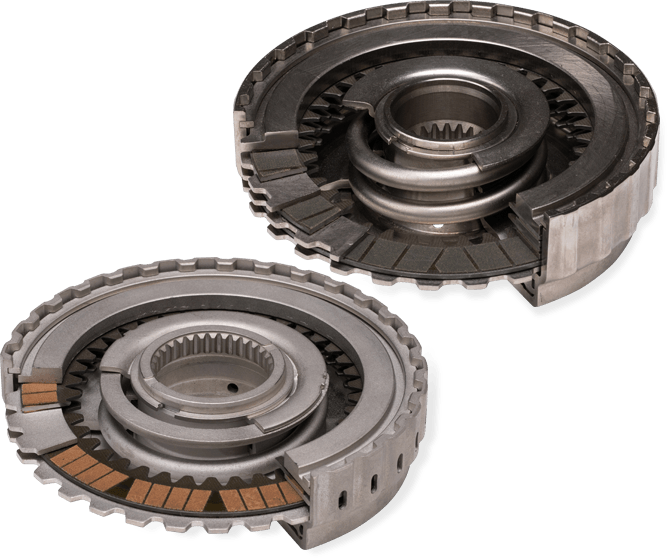

FR 10-speed Transmission Clutch

Triple clutch and single clutch integrating three clutches in one unit use an aluminum alloy effectively in its component to make substantial lightweight design possible.

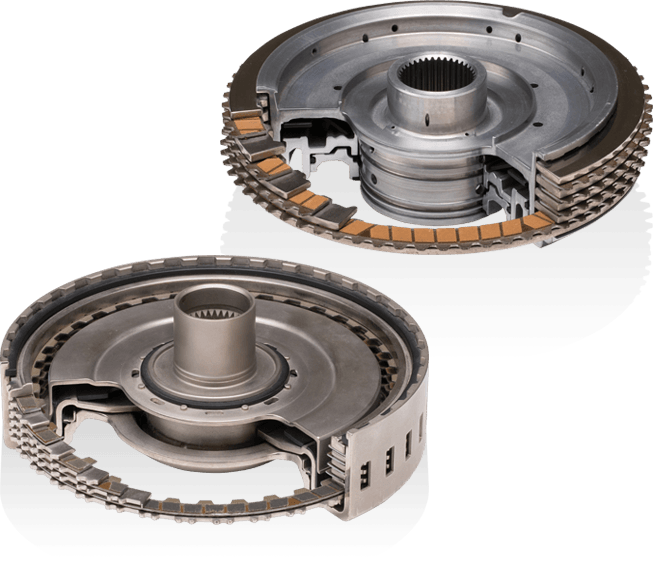

FF 9-speed Transmission Clutch

Improvement of fuel efficiency and compact design of the transmission are made possible using the clutch disks with both low drag torque and superior heat resistance.

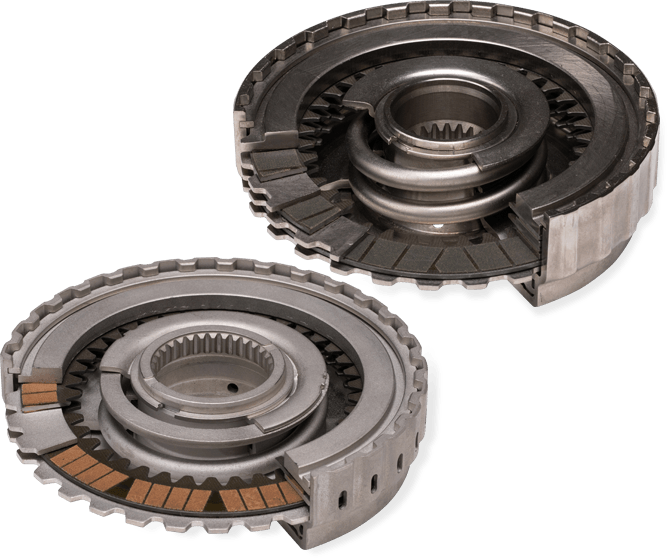

FF 8-speed Transmission Clutch

Clutch housing with high tooth profile accuracy of both inside and outside is realized using FAD manufacturing process.

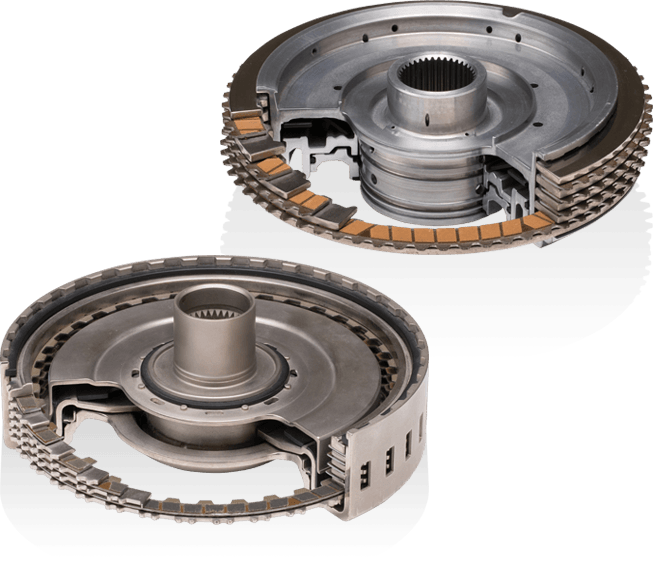

FR 6-speed Transmission Clutch

High-capacity clutch with space-saving design realized by double structure equipped with two clutches. Housing made by flow forming process and aluminum ally die cast piston are used.

Automotive Clutch for HEV

Automotive Clutch for HEV

Compact clutch with drag torque reduced using clutch disks made by the FAS process.

Clutch for Twin-motor Drive Unit

High-capacity friction material and low drag torque disk made by the FAS process are used. Brings improvement of fuel efficiency while driven by the engine.

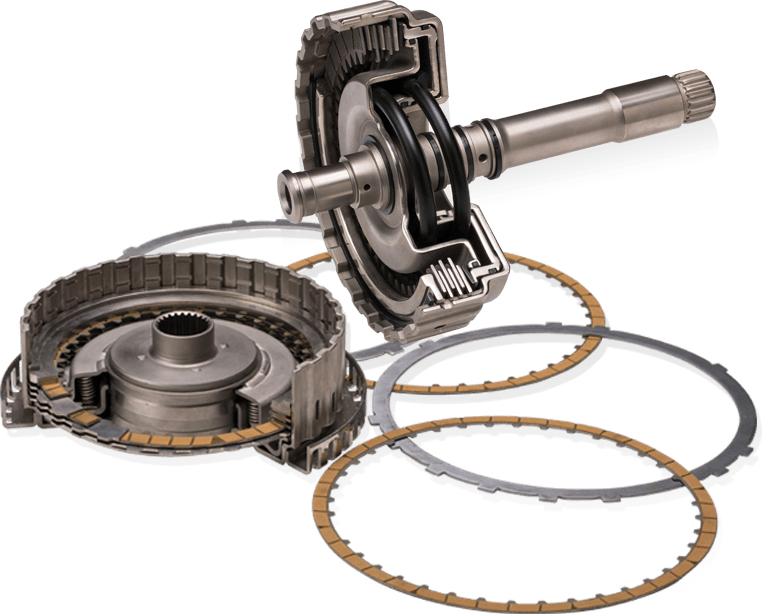

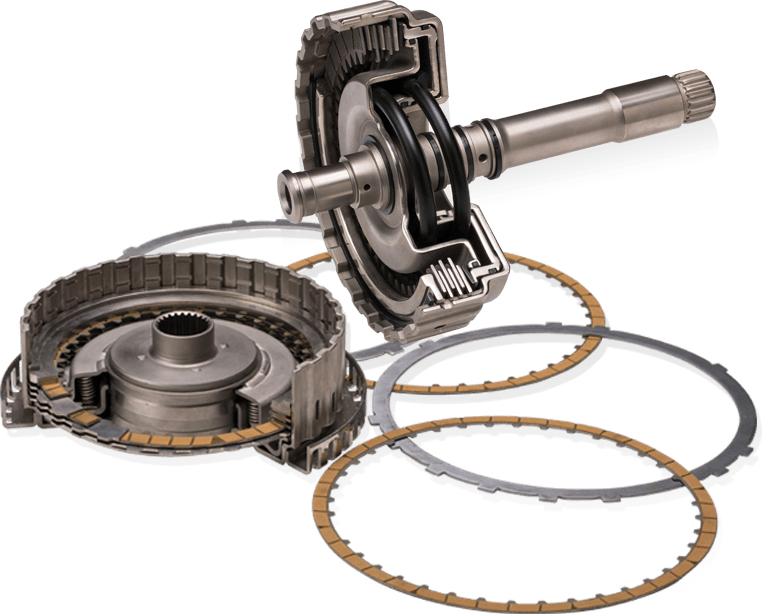

Automotive Clutch for CVT

Forward Clutch and Reverse Brake Disk

Clutch with integrated shaft using high μfriction material with compact design realized.

Forward Clutch: Shift select function without changing vehicle control system is realized by optimized friction material and tuning of response by sealing material.

Clutch for Reverse Brake: Drag torque is reduced by optimized design of the friction material groove shape. Brings improvement of fuel efficiency while forward driving.

Forward Clutch and Reverse Clutch for K-cars

Clutch with improved durability and low manufacturing costs realized by using s the ingle drawing process of the clutch guide made of high tensile strength steel sheets and high durability friction material considering the use pattern of K-cars.

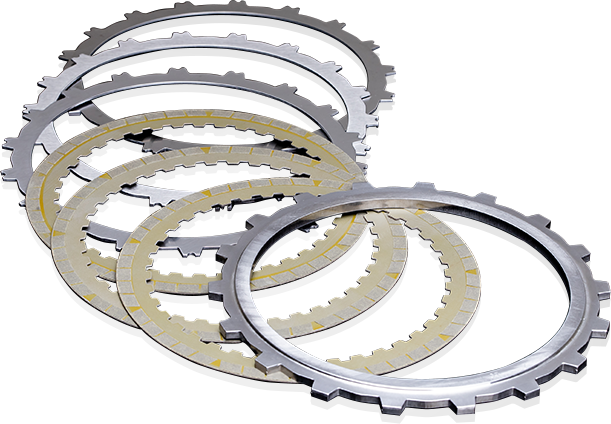

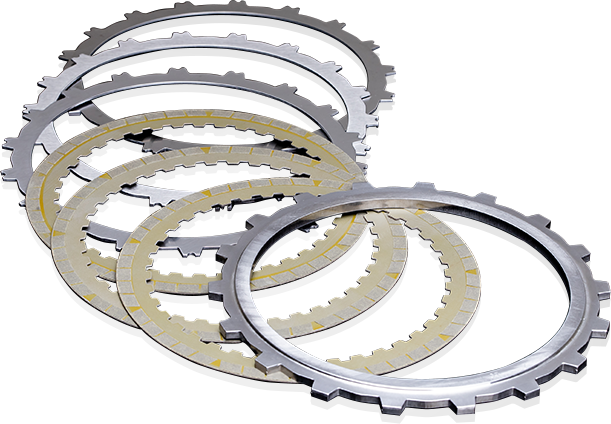

Various Types of Wet Disks

FSD: Groove shape of the segment can be selected depending on the required performance.

FAS: Manufacturing process that makes reduction of drag torque and improvement of yield possible.

Lock-up Clutch

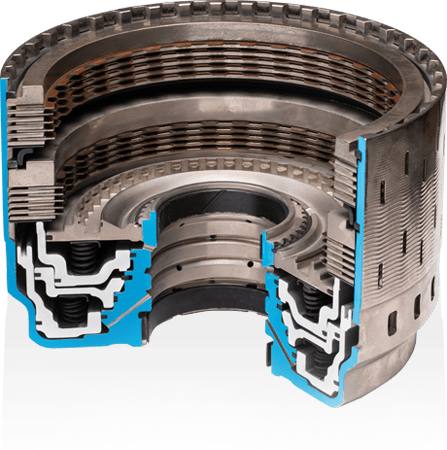

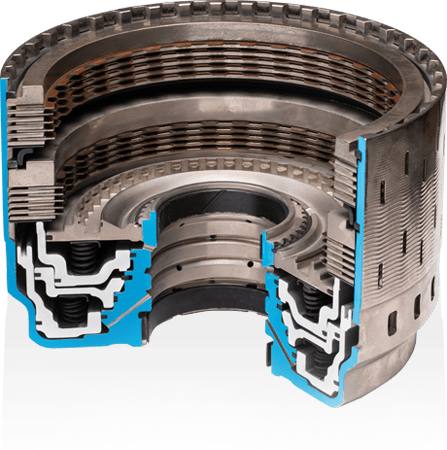

Multi-disk Lock-up Clutch

Range of lock-up function is substantially increased by the use of low spring constant damper and multi-disks clutch, which brings improvements to fuel efficiency.

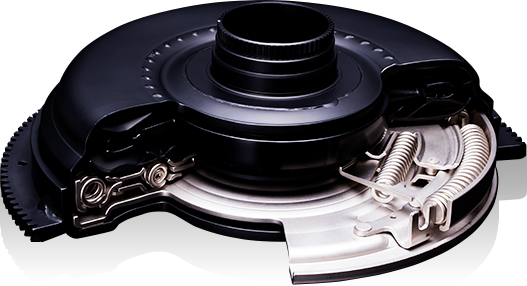

Twin Damper for Lock-up Clutch

Range of lock-up engagement is increased by use of low spring constant damper, which brings improvements to fuel efficiency.

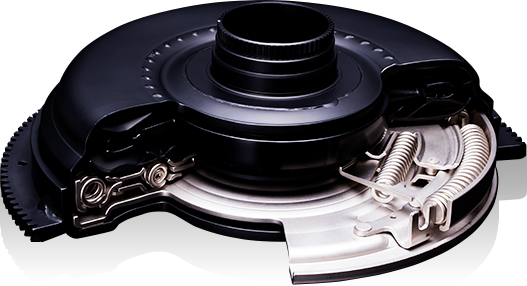

Single-disk Lock-up Clutch

Long torsion spring of arc type is used, to make lock-up engagement in low-speed range, achieving substantial improvement of fuel efficiency.

Two straight damper springs are installed in series, which improves damping performance significantly owing to low spring constant and reduced dynamic hysteresis torque, which brings improved fuel efficiency.

Manual Transmission

Dry Single Disk Clutch

Clutch commonly used for small to large vehicles.

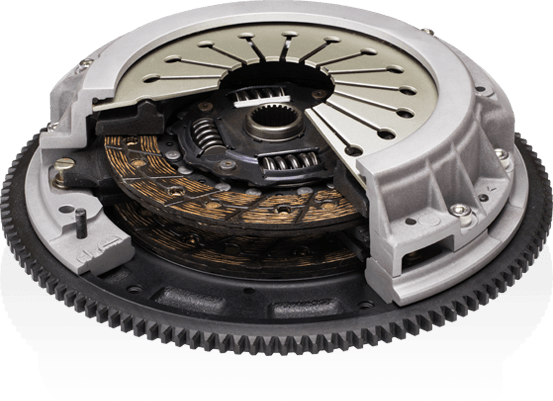

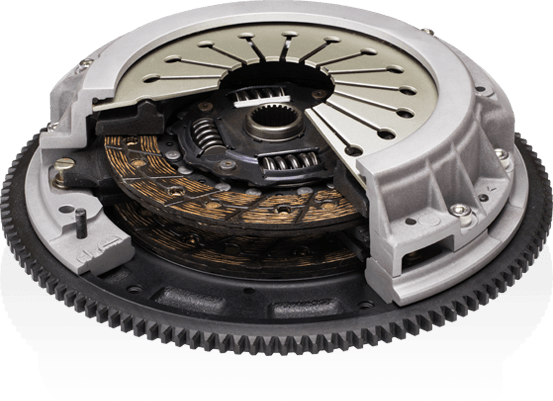

Dry Twin Disk Clutch

Pressure disk friction tracking mechanism is used for high-speed rotation and high power-output, which brings significant improvements to the lifetime of the clutch.