Approach to New Businesses

Since the beginning of the 21st century, the automotive industries experienced accelerated introduction EVs, FCVs, and PHVs, and the motorcycle industries also experienced the shift to EVs at remarkable speed. Such a trend causes revolutionary innovations in various fields of technologies not limited to the field of mobility applications and evolution of technologies is limitless.

FCC established the New Business Development Division to furnish our development, engineering, and manufacturing capabilities focused on clutches in different ways to society and continues research. Our aim is a new technology that will precede a new era that is beyond the clutch and mobility business. The business only FCC can do.

FCC intends to use the position of global No. 1 market share of clutches to seek the opportunity.

NEW BUSINESS

Three Mainstays of New Business

-

Development of EV Related Products FCC will engage in research and development of the products for EVs in the product areas beyond clutches and CVT systems.

MORE INFOkeyboard_arrow_right -

PAPER Applied Product Development FCC makes an effort for application in other areas, such as high-performance fuel cell stacks, water treatment papers used to filter out impurities, and catalyst, utilizing our unique papermaking technology of FCC acquired by manufacture of friction materials.

MORE INFOkeyboard_arrow_right -

Business Development in New Business Field FCC challenges the creation of innovative values that FCC can contribute to the society of the next generation, getting a picture of the global market trend without being bound by the existing technologies and business areas.

MORE INFOkeyboard_arrow_right

Development of EV Related Products

Development of EV Related Products

Looking ahead at the electric mobility society, FCC develops products for EVs in the area beyond clutches and CVT systems in cooperation with universities and venture businesses.

PAPER Applied Product Development

PAPER Applied Product Development

FCC makes research and development of products in completely new business fields using the papermaking technologies acquired through manufacture of friction materials.

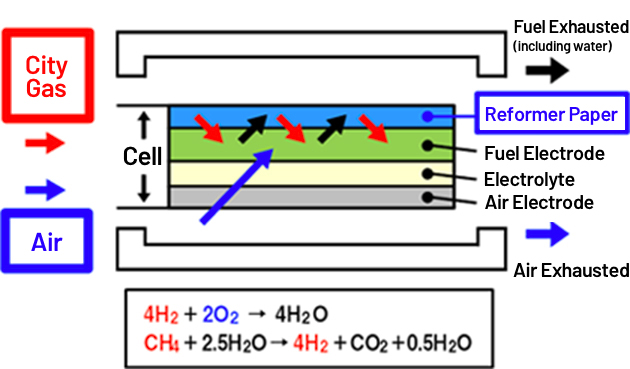

Development of New Fuel Cell Stacks

Integrates three functions in one unit to

realize high efficiency and for compact design

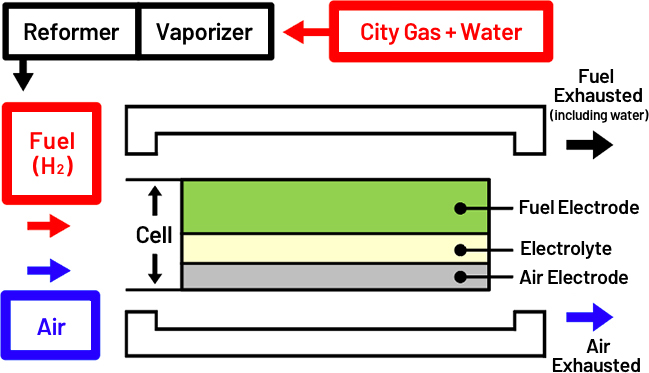

Fuel cell stacks used in home generators. FCC is conducting research to realize highly efficient power generation incorporating high-efficiency paper using our papermaking technology in the core device of the generator. This eliminates the reformer and water vaporizer incorporated in the conventional SOFC, and significant compact designs and low costs are realized. Water produced in the fuel cell to be wasted can be used for reforming, which contributes to high performance and reduction of greenhouse gas emissions.

Differences between Conventional SOFC and Integrated Reformer Fuel Cell

| Conventional SOFC | Integrated Reformer Fuel Cell | |

|---|---|---|

| 1 | Reforms city gas using a vaporizer and reformer (generation of hydrogen) | Water vaporizer and reformer are not required |

| 2 | Oxygen in the atmosphere flows into the air electrode | Oxygen in the atmosphere flows into the air electrode |

| 3 | The fuel (H2) flows from the fuel electrode | The fuel (city gas) flows into the paper Reforms city gas in the paper (generation of hydrogen) The fuel (H2) flows from the fuel electrode |

| 4 | Oxidation of hydrogen on the fuel electrode surface (H2O is produced) | Oxidation of hydrogen on the fuel electrode surface (H2O is produced) |

| 5 | Electromotive force is produced (power generation) | Electromotive force is produced (power generation) |

| 6 | Excess fuel and water produced are exhausted | Water produced is reused for reforming |

-

Conventional SOFC

Schematic Diagram of Cell Cross Section

-

Integrated Reformer Fuel Cell

Schematic Diagram of Cell Cross Section

RO/UF Membranes protecting Water Quality on the Earth

For Wastewater Treatment, Industrial Boilers, and Power Generation Plant

RO/UF Membranes used in Wastewater Treatment System and in Water Treatment System for Industrial Boiler and in Power Generation Plant.

Thin thickness paper and thin-film technologies acquired by the progress of FCC’ s core technologies (papermaking) are used to increase the production capacity of the permeated water volume, and processing efficiency is expected to increase.

FCC aims at global market as the needs for reuse of treated water is increasing because of concerns for water pollution.

Removal Catalyst that is Environmentally Friendly

Exhaust Emission Removal Catalyst is already realized and proceed to the Next Step

In 2008, FCC succeeded in the development of exhaust emission purification catalysts (paper catalysts) using the technologies for manufacturing clutch friction material and the wet papermaking process. In 2011, the production of the catalytic converters for small outdoor power machines equipped with such catalyst started. FCC plans to advance development of such technologies aiming at development of the catalyst to remove PM in the manufacturing plant to the market primarily in developing nations where air pollution is a serious problem. FCC will contribute to society using our proprietary technologies to reduce the number of people suffering from respiratory and cardiac diseases through the reduction of hazardous substances like PM in the atmosphere.

In 2008, FCC succeeded in the development of exhaust emission purification catalysts (paper catalysts) using the technologies for manufacturing clutch friction material and the wet papermaking process. In 2011, the production of the catalytic converters for small outdoor power machines equipped with such catalyst started. FCC plans to advance development of such technologies aiming at development of the catalyst to remove PM in the manufacturing plant to the market primarily in developing nations where air pollution is a serious problem. FCC will contribute to society using our proprietary technologies to reduce the number of people suffering from respiratory and cardiac diseases through the reduction of hazardous substances like PM in the atmosphere.

Business Development in New Business Fields

Business Development in New Business Fields

Innovative Business by Borderless Approach

What the clutch manufacturer can contribute to in the next generation society where the basis for the existence of clutches changes due to advances in electrification? Maximizing the use of FCC’s technologies and resources established in the large global automotive and motorcycle market, what solutions can FCC provide to the issues of the future society?

The areas covered by the New Business Development Division cover all industries and fields of application expanding from the mobility applications like EV and FCV products that are still within the extension of FCC’s existing business.

FCC will continue to study the creation of a stage where the strength of FCC with superior expertise and technological capability can be demonstrated and to continue research and development expanding our horizons.