World-Class Press Technology

Press Technology

(plastic processing technology)

that can quickly form complex and precise shapes

Press forming technology.

There are three main press technologies: blanking, bending, and forging. A wide range of knowledge and experience is required to implement these technologies, including the characteristics of material and die mechanisms. FCC, fully using the know-how cultivated through precision equipment manufacturing, owns technology that enables forming in a single shot and can contribute to lighter weight, process saving (near-net-shape), and cost reductions.

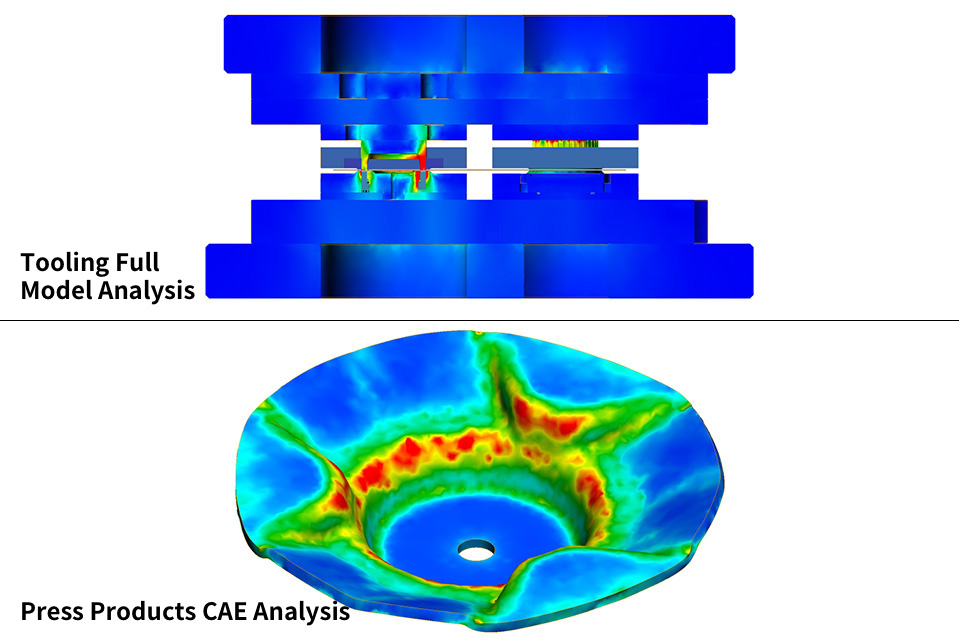

Predictive Analysis for efficient development

We have experience and the various threshold values for forming, and die stress to maximize the process while identifying any potential for defects, shortening the overall development timeline

Intial design studies performed with Mass Production in mind, including stress and strain date and rapid CAE analysis streamlining the development process.

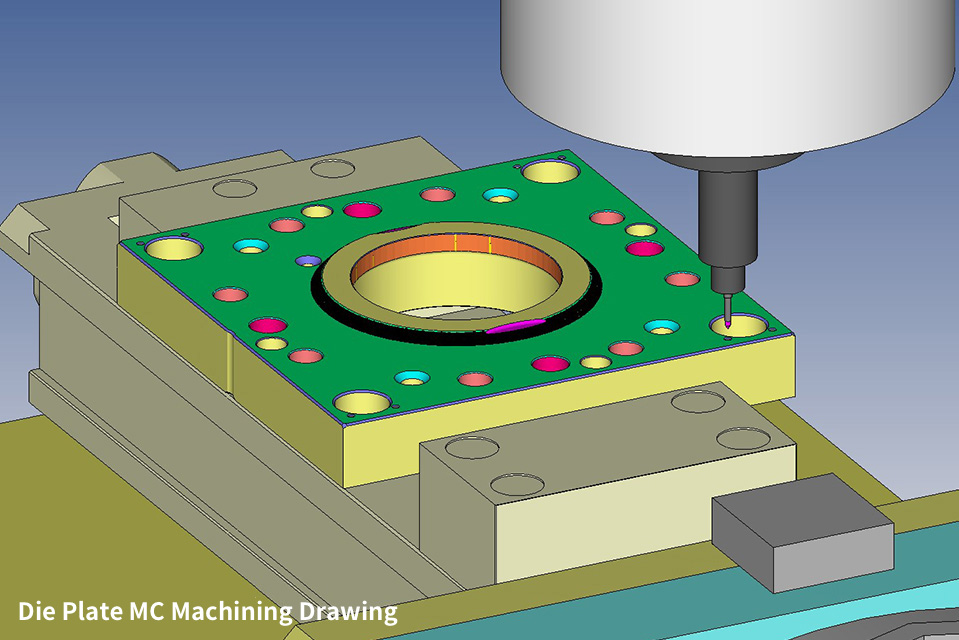

Die Design Capability

Based on high-precision CAE analysis, products with complex shapes (motions) can be exactly reproduced in a single shot.

Since we perform from design to manufacturing of 3D dies, the process and cost are reduced through direct transfer to the processing program after a 3D model is designed.

Expedited Trials and Events

Our adjustable double-action presses and business know-how allow optimized condition settings and prototyping which fullfill product requirements.

Analysis and Evaluation

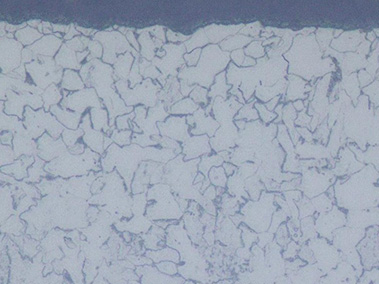

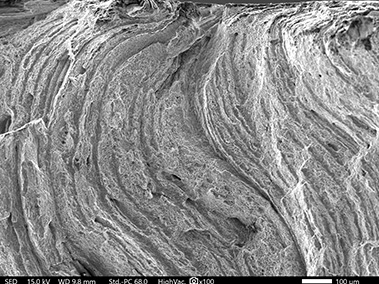

Pursuit of the true cause of defects and prompt response through material analysis (composition, microstructure, mechanical properties) and product evaluation (accuracy, strength).

Analysis and evaluation data accumulated over an extended period of time are fed back into product and press manufacturing, playing a key role in quality improvement.

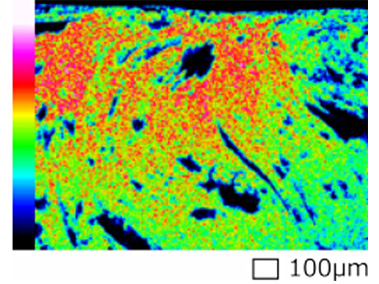

Mechanical property analysis (tensile test appearance)

Steel cross-sectional structure Evaluation

Surface condition analysis by SEM

Element analysis by EDS

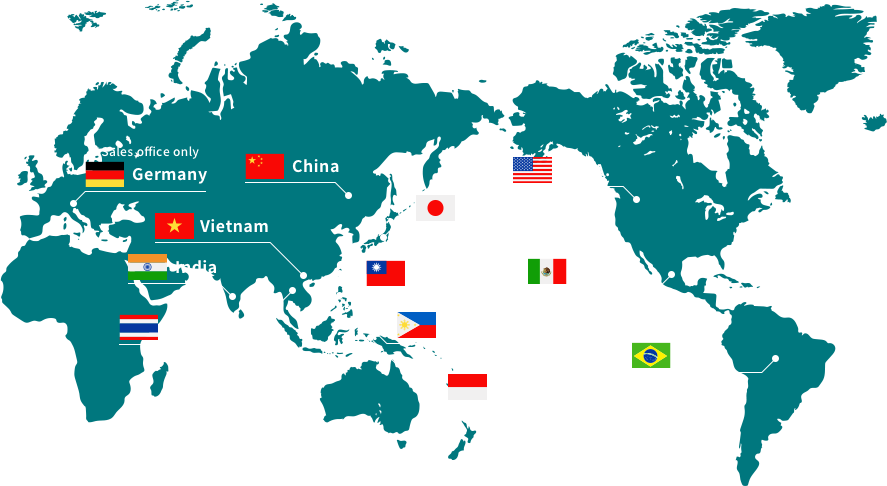

Overseas Production

FCC, which has a global presence with locations in Asia, North America, and China, possesses the same production facilities and development technologies as we do in Japan in our overseas plants, which makes it possible to supply high-quality products to the local supply chain in a timely manner.

FAD Method (sheet steel drawing technology)

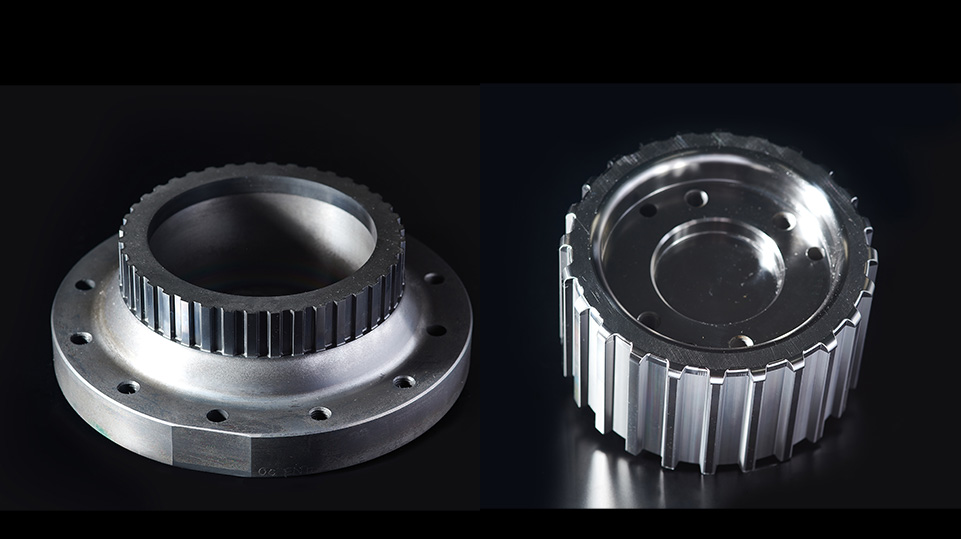

FCC's unique press technology, the FAD (FCC Advanced Drawing) method, enables a variety of forming with a single stroke of the press.

Streamlining production processes, mass production costs and cycle time will be significantly reduced for products, including clutch drums.

We also possess double-action forming technology to realize more complex and precise processing.

Features / Advantages

Increased Productivity by Reducing the Number of Processes

To form sophisticated tooth profiles that require multiple processes, the FAD process completes the process in a single pressing. It reduces the cycle time and realizes cost reductions through reduced processing loads.

Offering Best Product Shapes

FCC has cultivated its expertise in press technology through more than 30 years of research and development.

Based on data accumulated through more than 10 years of experience in CAE analysis technology, we propose optimal lightweight, high-precision, and space-efficient product shapes.

Ensured Strength and Durability for Peace of Mind and Safety

Using the FAD process products that require different thicknesses for different zones can be formed in one process. This creates high quality processing that combines accuracy and speed for automotive parts. This includes clutch drums, which require high strength and durability.

Supporting Mass Production with expedited launch capabilities

Products for a variety of applications are processable using a general-purpose mechanical press.

Space-saving and versatile

Comparison of GROB Rolling and FAD Method

Greatly Contributing to Cost Reduction by Adopting FAD Method

| FAD Method | GROB Rolling Method (general tooth profile forming method) |

|

| Number of Processing Cycles | 1 (single stroke) | 5 |

| Forming Time | 7 seconds | 40 seconds |

GROB rolling method was regarded as the mainstream in the processing working of tooth profile parts.

The tooth profile of product is processed by two roller-shaped press dies.

Solution to such issues as the following:

Reduce product processing cost

Produce high quality products which are currently produced locally, at overseas locations

Efficiently produce durable parts

Offer solutions for products that meet customer needs

Other Technologies Owned

- Double-Action Forming Technology

- Transition to double motion in a single action, high load gas cushion in the die to reproduce a double motion

- Cold Forging Spline Forming

- Spline forming by unique cold forging method

- Sheet Metal Forming Technology

- Press finish without heating

- Near Net Shape

- Minimized processing allowance

- Barring Technology

- Prevention of cracking by the multistage forming method

- Forming Technology for Reduced Processing

- Elimination of edge cutting process using upset forging

- Progressive Technology

- Bridge shape optimization / Reduced processing by blank processing breakdown

- Blanking Technology

- Establishment of high shear range in high strength steel plates by internal/external shaving process technology

- Blanking Technology

- Responding to motorized products (separators / motor cores)

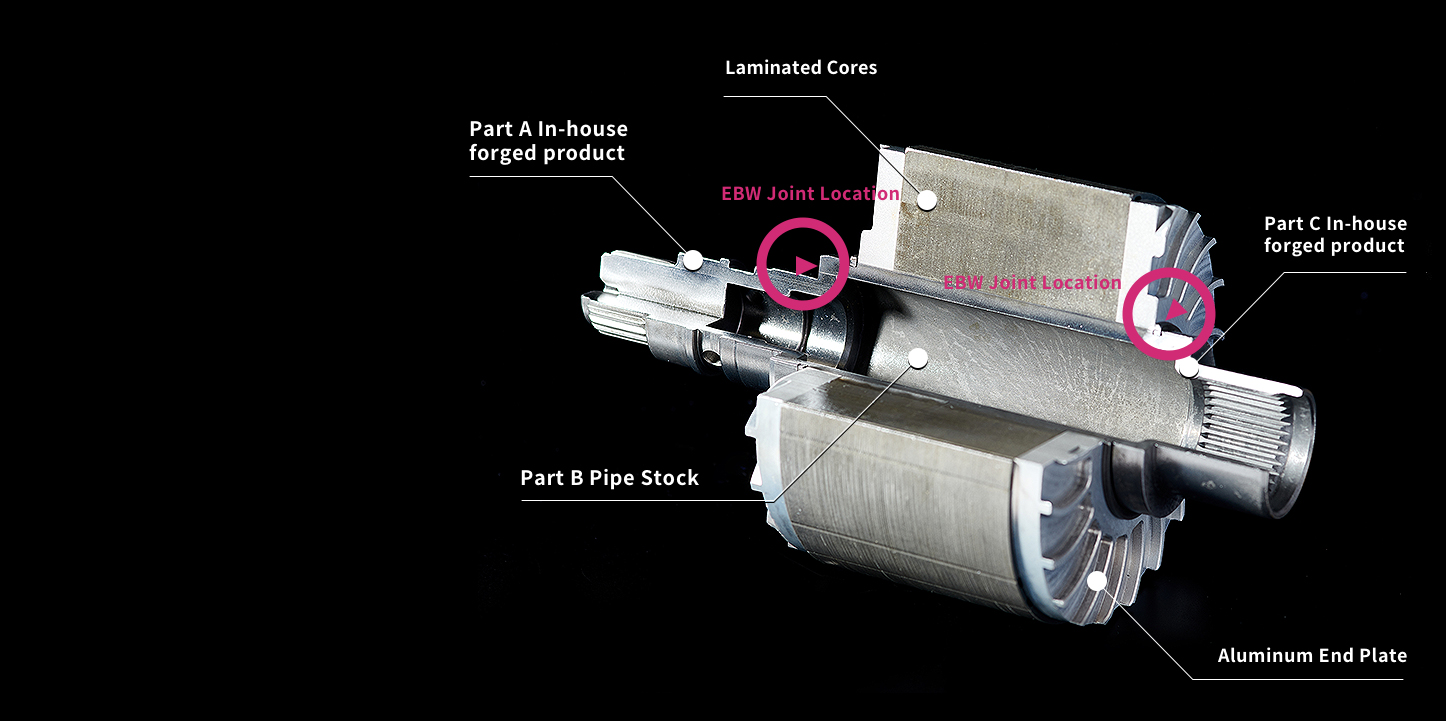

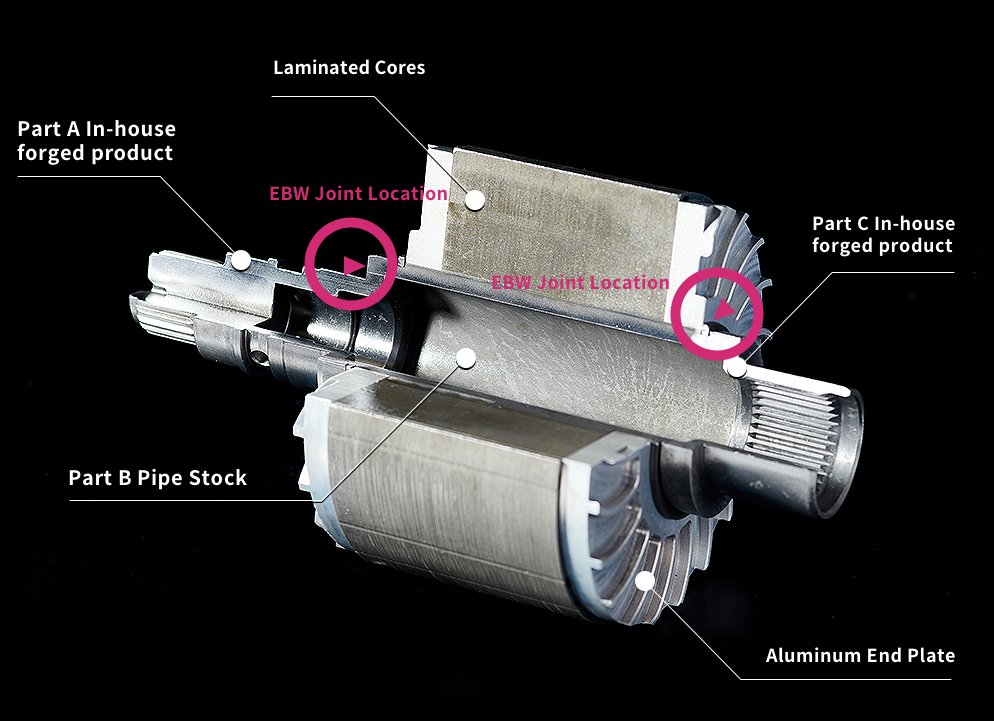

Hollow Rotor Shaft for Four-Wheel Vehicles

Products with high design flexibility that cannot be imitated by others,

using the high-precision processing technology and joining technology cultivated through clutch manufacturing.

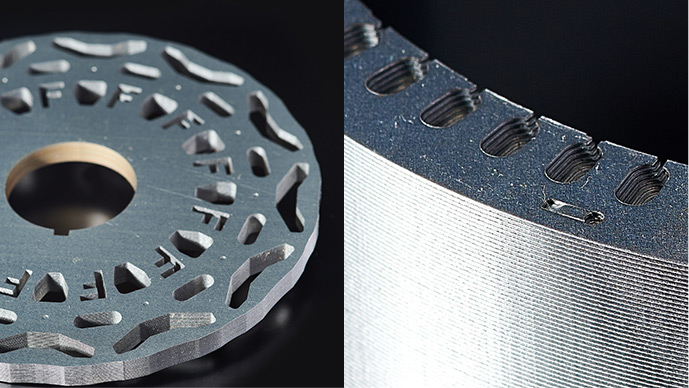

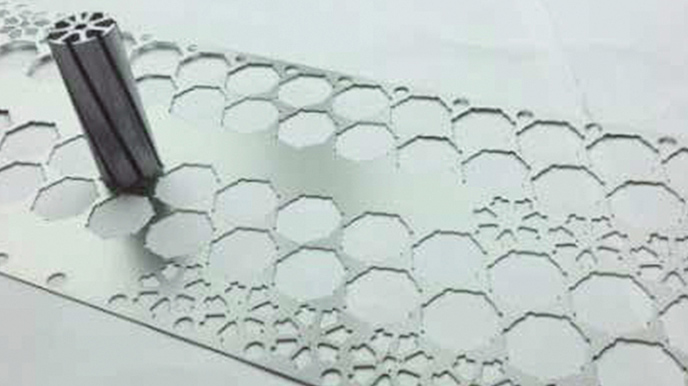

Motor Cores / Laminated Cores for Drives

Mass Production Dies: Co-Processing, Rotated Lamination, Split Stators

Multiple Blanking Laminated Cores

Layout with Improved Material Yield