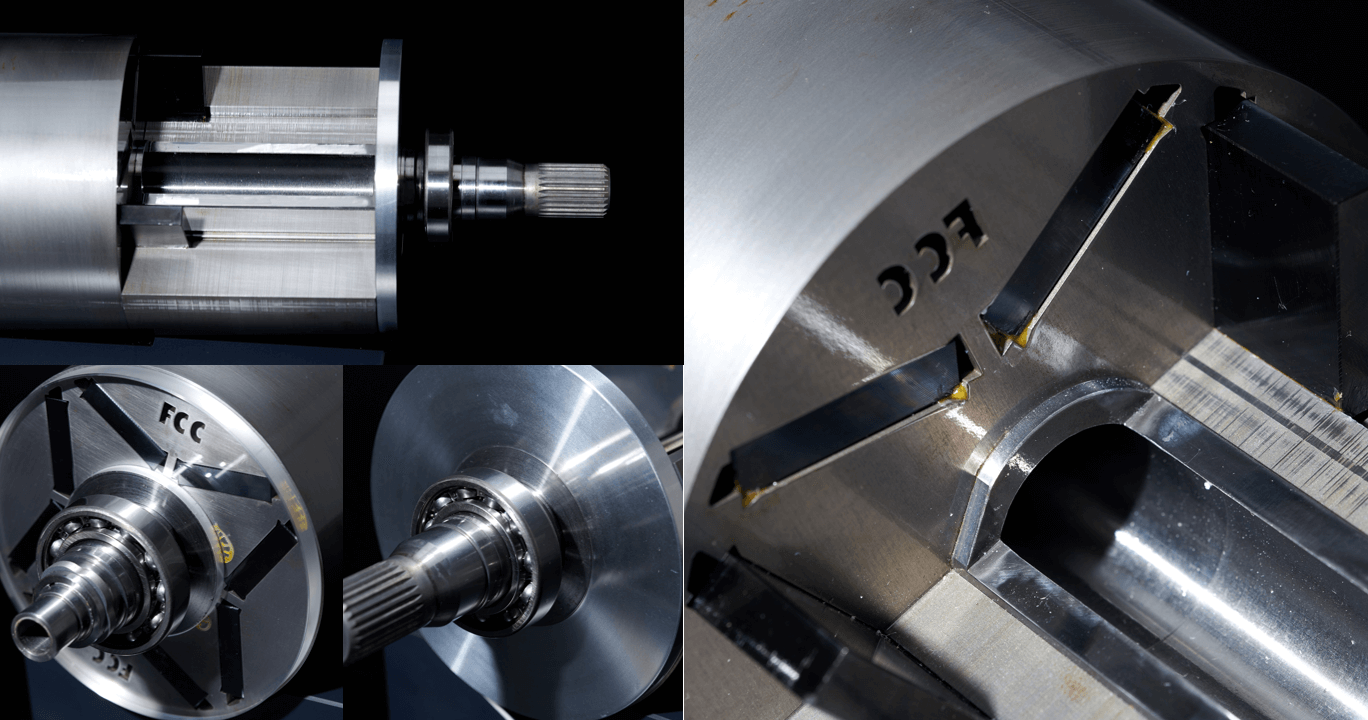

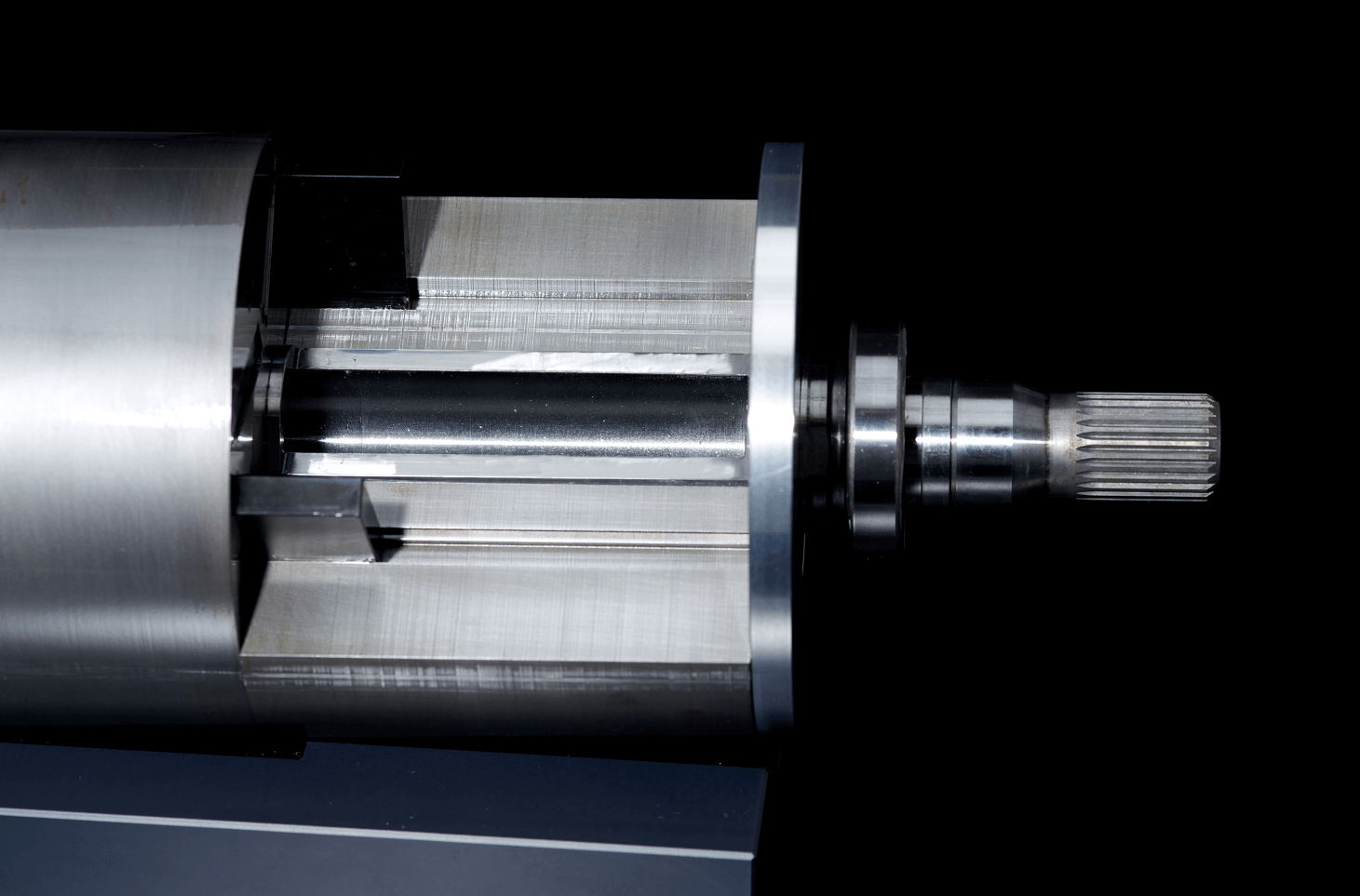

(Two-piece or three-piece) selectable shaft construction depending on the needs as the component with assured functions based on consistent development and manufacture by FCC

Proposal of Automotive Motor Core and Laminated Die Developed by FCC

- Press Technology (Draw and Press Forming)

- Combined Technologies

- Joining Technology

- Mobility

- INDEX

The rotor core and hollow shaft developed by FCC are supplied as the assembly

Technical Advantage: Inhouse Development and manufacture of the Laminated Core + Rotor Shaft

Integrated development from manufacture of laminated core press dies to stamping and to manufacture of the rotor shaft is provided by FCC. This will contribute to man-hour savings in the development of shaft core cooling technology for smaller and higher-speed motors

Technical Advantage: Joining Technology and Quality Assurance of the Joint

[Technology]

Divided shaft with negligible heat strain and high shaft balance is realized using EBW

Results with this Construction: 1.5 g・cm or less by two-piece construction of Φ45 × 400 L.

[Guaranteed]

EBW has long been used to join the AT clutch guide with the hub body for automobiles

▸Evaluation of strength from CAE analysis to actual product test can be consistently made by FCC in-house

Divided shaft with negligible heat strain and high shaft balance is realized using EBW

Results with this Construction: 1.5 g・cm or less by two-piece construction of Φ45 × 400 L.

[Guaranteed]

EBW has long been used to join the AT clutch guide with the hub body for automobiles

▸Evaluation of strength from CAE analysis to actual product test can be consistently made by FCC in-house

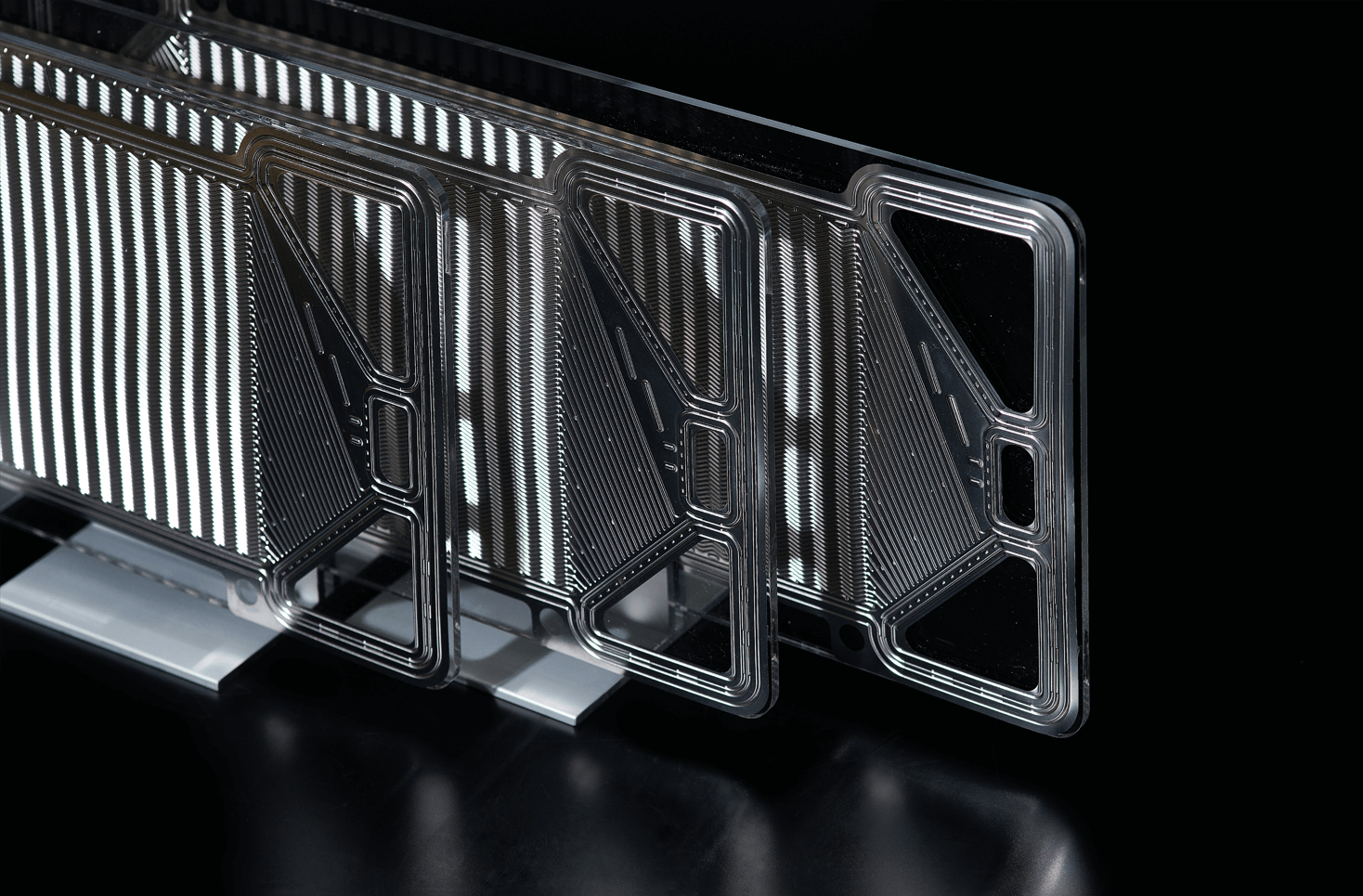

Manufacture of Precision Press Dies for Motor Core

Flint Co., Ltd., (Onga-gun, Fukuoka Prefecture), 100% subsidiary of FCC, can provide analyses to testing as a company of professionals specialized in the manufacture of the motor core precision press dies, in addition to engineering and manufacture of the laminated progressive dies by introduction of 300-ton (3.7 m bolster) high-speed press machines.

Technology and Development

Related Articles

Potential of Functional Ceramics made possible by Flexible Ceramic Paper Design Technology

- Papermaking and New Material Technology

- Manufacturing Field

- Environmental Protection

- Mobility

Introduction of Technologies using Carbon Nanotube, the Nanomaterial

- Papermaking and New Material Technology

- Environmental Protection

- Mobility

![[Manufacturing Patent Pending]Reduction of Manufacturing Costs and Improvement of Cooling Performance are realized by Hollow Pipe Cast-in Technology](/en/tech/results/uploads/entry/06e423fcacc22ebf1478de98c64efa8d.jpg)

[Manufacturing Patent Pending]Reduction of Manufacturing Costs and Improvement of Cooling Performance are realized by Hollow Pipe Cast-in Technology

- Precision Aluminum Casting

- Manufacturing Field

- Environmental Protection

- Mobility

Precision Aluminum Diecast Products realizing 100% Use of Sustainable Materials, Lightweight Design, and Improved Cooling Capacity

- Precision Aluminum Casting

- Manufacturing Field

- Environmental Protection

- Mobility

Development of Small Motors for Mobility Application

- Precision Aluminum Casting

- Press Technology (Draw and Press Forming)

- Combined Technologies

- Joining Technology

- Mobility

Proposal of Automotive Motor Core and Laminated Die Developed by FCC

- Press Technology (Draw and Press Forming)

- Combined Technologies

- Joining Technology

- Mobility

Development of FC Separator for FCV

- Press Technology (Draw and Press Forming)

- Mobility